Van Borselen Filters delivers top-quality products, available from stock

Are You Searching for a Y-Strainer?

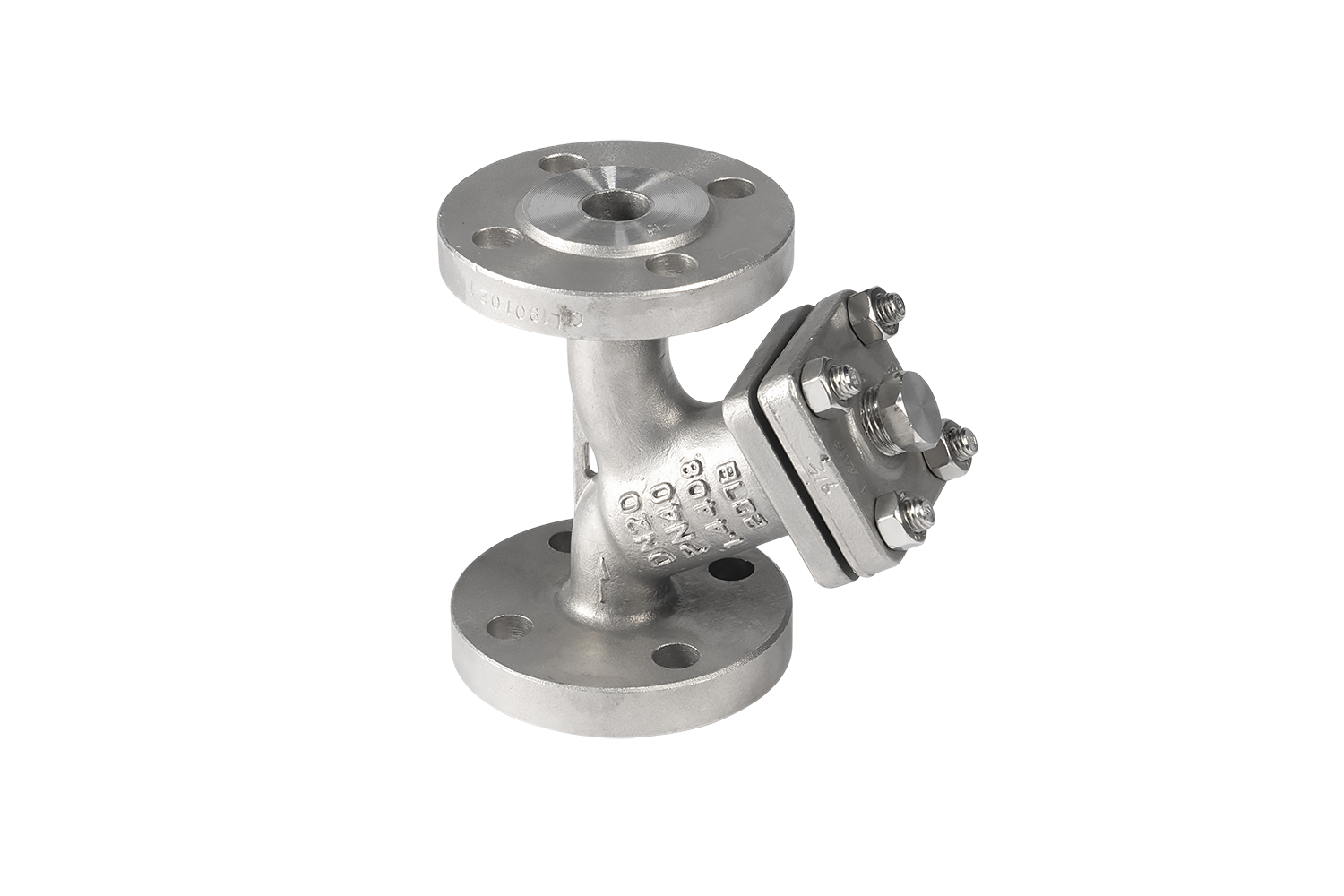

A Y-strainer—also known as a Y-filter—is the ultimate solution for effectively removing particulate contaminants from liquids, gases or steam. At Van Borselen Filters, we supply robust stainless-steel Y-strainers designed for a wide range of applications, including the chemical, food & beverage and water treatment industries. Our Y-strainers safeguard your equipment against clogging and wear, extend the service life of your installation and boost overall process efficiency. They are available in various sizes, connection types and custom filtration ratings to suit your specific needs.

Y-Strainer – Reliable Protection for Process Installations

The Y-strainer—also known as a Y-filter—is an indispensable component in industrial filtration systems. Its stainless-steel housing provides the structural backbone that supports and protects the internal components. By removing solid particulates from liquids, gases, steam, water and other process fluids, the Y-strainer safeguards pumps, valves and other sensitive downstream equipment from clogging and damage.

- Y-strainer (threaded connection)

Available with NPT or BSP male threads, sizes ranging from ½″ to 4″, in various pressure classes (ANSI 150–300, PN10–PN40). - Y-Strainer (Flange)

Offered with DIN or ANSI flange faces, in sizes from DN15 to DN100 and pressure ratings from PN10 to PN40 (ANSI 150–300).

All variants come in multiple materials—stainless steel (304/316L), cast iron, or engineered plastics—to suit chemical, petrochemical, water treatment, food & beverage and pharmaceutical applications.

Key Components

- Housing (Body): Rugged stainless-steel construction for high pressure and temperature resistance.

- Cover (Cap): Bolted closure with gasket seal for leak-free performance and quick access.

- Screen Element: Perforated or wire-mesh cartridge, available in mesh sizes from 10 µm (micron) to 2 mm (coarse).

- Gasket: PTFE or graphite gasket to prevent leakage between body and cover.

- Bolts & Nuts: Grade A2 or A4 stainless steel for corrosion resistance.

- Blowdown/Drain Plug: Allows in-line flushing of accumulated debris without disassembly.

Benefits of Our Y-Strainers

Compact, Space-Saving Design: Low installation footprint for both horizontal and vertical piping layouts.

Easy Maintenance: Quick-release cover and drain port enable fast cleaning without interrupting the process.

Wide Filtration Range: From coarse solids removal (2 mm) down to fine micron filtration (10 µm).

High Pressure & Temperature Capability: Suitable for services up to 16 bar and 200 °C, depending on material.

Versatile Mounting: Can be installed in horizontal (recommended) or vertical orientation.

Durable Construction: Corrosion-resistant materials ensure long service life under harsh conditions.

Whether you need a simple dirt trap or a high-performance strainer for critical processes, Van Borselen Filters will help you select the right Y-strainer for your application.

Maintenance & Inspection

Regular maintenance is crucial to maximize strainer life and performance. We recommend:

- Periodic Inspection: Check differential pressure across the screen to detect clogging.

- Routine Cleaning: Open the cover or use the blowdown plug to flush out debris.

- Component Check: Inspect the screen element for wear and replace if mesh is damaged.

- Operating Conditions: Monitor pressure and temperature to ensure they remain within the strainer’s ratings.

Installation & System Optimization

For optimal operation:

- Positioning: Install the Y-strainer horizontally with the cover facing downward, so solids settle into the blowdown port. Vertical installation is acceptable for gas services.

- Correct Sizing: Match the nominal diameter (DN or NPS) and pressure class to your piping.

- Pre-Filtration: Use a coarse inlet strainer upstream to capture large debris and extend the life of the Y-strainer.

- Complementary Components: Pair with check valves or pressure gauges to protect and monitor your system.

With proper installation and maintenance, your Y-strainer will deliver years of trouble-free service, ensuring clean process fluids and maximum equipment uptime.

Our products:

Learn more?

Contact us

If you would like to receive any additional or specific information about our product range, or if you would like one of our account managers to visit you, please do not hesitate to contact us.