Van Borselen supplies portable integrity testers for testing the integrity of air or fluid membrane filters. These testers are available for the food industry and the pharmaceutical market.

The Integrity testers of Van Borselen have been used worldwide for over 25 years and are available in two portable models:

BorsoTEST-FB (Food) - easy to use, industry standard.

BorsoTEST-PH (Pharmaceutical) - with built-in access for user passwords, traceability, and audit tracking.

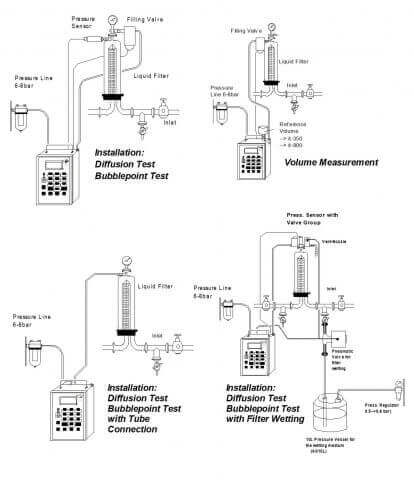

The instruments are configured for: Pressure drop (Diffusion flow), bubble Point and Water Intrusion testing (WIT) over a test pressure range of 350 - 6000 mbar.

Bubble Point test:

A bubble point test is a method used to determine the integrity of a membrane filter. The test involves applying a high-pressure gas, such as air or nitrogen, to one side of the filter while the other side is submerged in a liquid, typically water. The test is performed by gradually increasing the pressure on the gas side of the filter until bubbles are observed on the liquid side. The pressure at which the first bubbles appear is known as the "bubble point."

The bubble point test is a measure of the largest pore size of the filter, and it can be used to determine if the filter is functioning properly and if it is suitable for the intended application. The bubble point test is also used as a quality control measure in the manufacturing process of membrane filters. It is important to note that bubble point test is mainly used for testing membrane filters, like BorsoPES-P filter cartridges.

Diffusion flow test:

A diffusion flow test, also known as a pressure drop or pressure decay test, is a method used to test the integrity of a membrane filter. The test involves applying a gas, such as air or nitrogen, to one side of the filter at a constant pressure and measuring the rate of pressure decay on the opposite side of the filter.

During the test, the pressure on the upstream side of the filter is held constant, while the pressure on the downstream side is monitored. A decrease in pressure on the downstream side indicates that gas is flowing through the filter. The rate of pressure decay is a measure of the filter's integrity and can be used to determine if the filter is functioning properly and if it is suitable for the intended application.

The Diffusion flow test helps to determine the filter's ability to pass the gas through it without any leaks, and it's useful to test the filter's performance in terms of flow rate, pressure drop, and other parameters like filter dirt loading, filter condition and filter life.

It is also important to note that Diffusion flow test is mainly used for testing microfiltration

Water Intrusion test:

Water Intrusion Testing (WIT) is a method used to test the integrity of a hydrophobic (water-repelling) membrane filter. The test involves applying a high-pressure water to one side of the filter while the other side is connected to a pressure gauge. The test is performed by gradually increasing the pressure on the water side of the filter until water is observed on the gauge side. The pressure at which water is first observed is known as the "intrusion pressure."

The Water Intrusion Testing is a measure of the filter's ability to repel water and it can be used to determine if the filter is functioning properly, if it is suitable for the intended application and if it is hydrophobic as required.

WIT test is mainly used to test hydrophobic membrane filters such as those used in gas separation, air purification, and other applications where it is important to prevent water from penetrating the filter. This test could be also used to check the filter's performance in terms of its water repellence, filter dirt loading, filter condition and filter life.

Features:

- Designed to meet 21CFR11-compliant environments.

- Easy to carry and rechargeable battery power. Robust, waterproof, stainless steel housing.

- Full range of integrity test protocols, including filter flushing and drying (additional accessories required).

- Simple, safe, and leak-free connections.

- Wide range of housing sizes from 0.1 to 32000 ml.

- Wide range of accessories available to simplify the filter integrity testing process.

- The BorsoTEST-FB and HP are the basic models which can be expanded to, for example, Ex-zone 1

Parameters:

- Diffusional Flow Measurement Range (ml/min): 1- 999

- Resolution (ml/min): 0.1

- Accuracy (@ ≥5 ml/min) %: 5

- Test Pressure (mbar): 350 - 6000

- Stabilisation Time (secs): 60 - 999

- Test Time (secs): 30 - 999

- Upstream System Volume (l): 1 - 32000

- Bubble Point

- Bubble Point Measurement Range (mbar): 450 – 5900 (with a min. of 100 mbar above the DF test Pressure)

- Resolution (mbar): 1

- Accuracy (%FS): 1

- Water Intrusion

- Water Intrusion Measurement Range (μl/t) (Water Flow): 100 - 99999

- Resolution (μl): 5

- Accuracy ( @ ≥100 μl/t) %: 5

- Test Pressure (mbar): 350 – 6000

- Stabilisation Time (secs): 60 - 999

- Test Time (secs): 30 - 999

- Hardware Volume (l): 1 - 32000