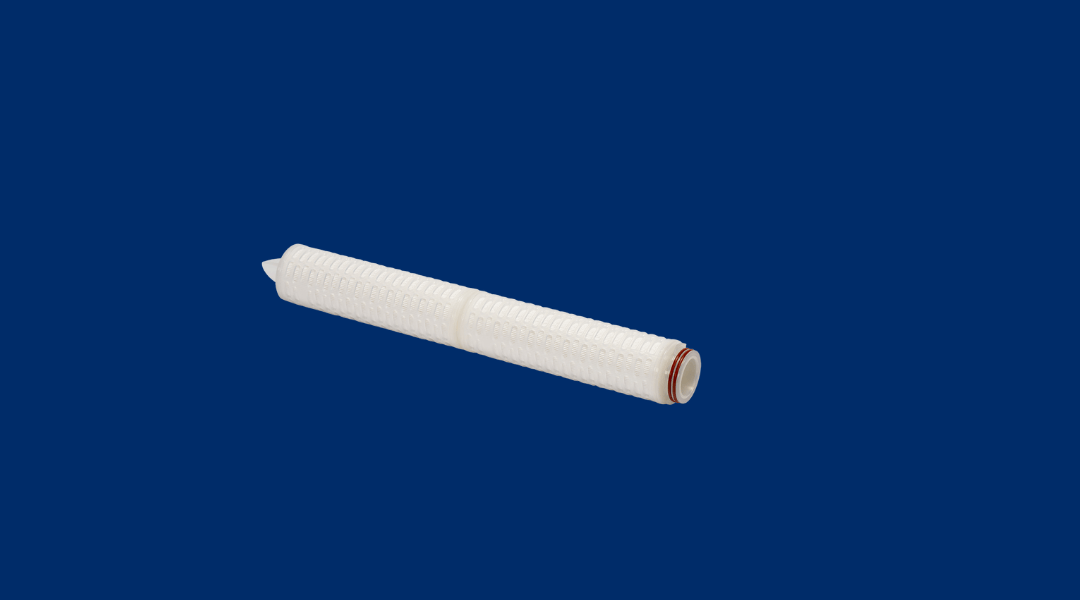

- Filter Cartridges

- PTFE Membrane

PTFE membrane filters for reliable sterile air and gas filtration

What is membrane filtration and how does it work?

Membrane filtration is an advanced separation technique that uses a semi-permeable membrane to separate liquids or gases. This membrane allows certain particles (such as water molecules) to pass through while retaining larger particles, microorganisms, salts, or contaminants. The separation is based on size, pressure, or chemical properties.

How does membrane filtration work?

During membrane filtration, a liquid is forced through the membrane under pressure. Depending on the pore size of the membrane, unwanted particles are retained and removed from the flow.

Benefits of membrane filtration

- Highly accurate filtration

Retains microorganisms, particulates, and dissolved substances down to the molecular level. - Energy-efficient

Often more efficient than thermal separation methods. - Compact systems

Membrane filters require minimal space and are easy to integrate into existing processes. - Versatile applications

Suitable for food & beverage, pharmaceutical, chemical, and water treatment industries.

Applications of membrane filtration

Membrane filtration is widely used in:

- Pharmaceutical manufacturing – for sterile filtration of air, gases, and liquids.

- Food & beverage processing – such as wine clarification and milk filtration.

- Water treatment – to remove bacteria, viruses, and chemicals.

- Chemical processing – for purification of solvents and process fluids.

Why choose PTFE membrane filters?

PTFE (polytetrafluoroethylene) is a chemically resistant and hydrophobic material, making it ideal for sterile filtration. Its stable pore structure, temperature resistance, and pressure tolerance ensure long-term reliability—even in demanding conditions.

Van Borselen Filters offers a wide range of high-quality membrane filters suitable for microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. Available in various membrane materials including PES, PTFE, Nylon, and PVDF, our filters are tailored to your specific application. Whether you require sterile air filtration, removal of microorganisms from process water, or protection of sensitive analytical instruments—Van Borselen provides the right solution.