What is porous sintered metal?

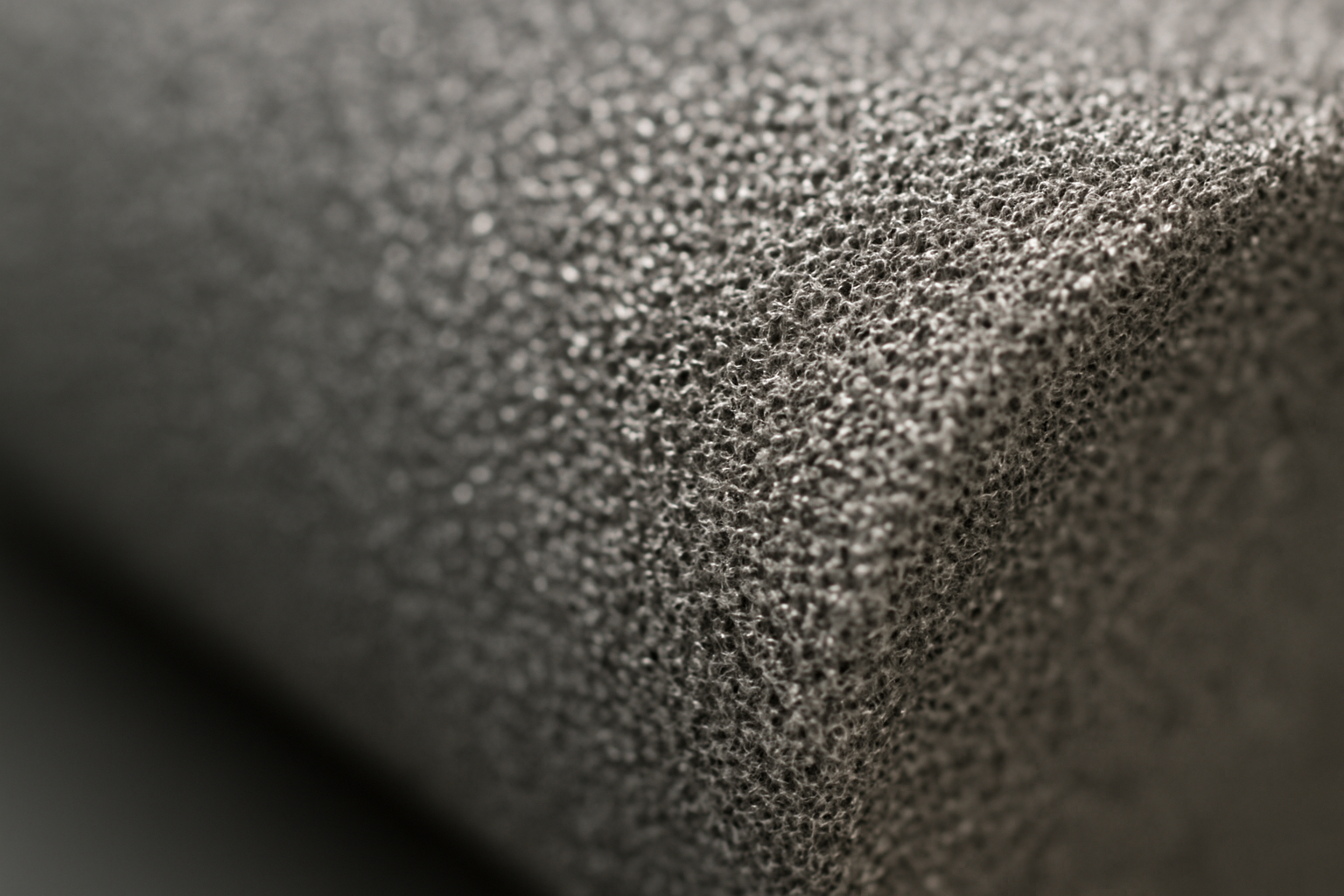

Porous sintered metal is produced by compressing fine metal particles and heating them to just below the melting point.

This creates a robust yet porous structure with a highly uniform pore distribution.

This results in:

- Consistent filtration efficiency

- Extended service life

- Reliable performance under demanding operating conditions

Depending on your process requirements, we select the appropriate metal alloy and pore size (ranging from 0.2 to 100 microns), ensuring you receive a filtration element precisely tailored to your application.

How is porous sintered metal manufactured?

Metal sintering is a controlled production process in which metal powder is compacted and then heated to a temperature just below its melting point.

The particles partially bond, forming a strong, rigid, and porous matrix.

This delivers stable filtration performance, even at elevated temperatures or under differential pressure.

The result: a filter element that is not only mechanically durable, but also highly reproducible—crucial for industrial processes with strict specifications.

Depending on your process requirements, we select the appropriate metal alloy and pore size (0.2 to 100 microns), ensuring optimal compatibility with your application.

The benefits of porous sintered metal

Porous sintered metal offers a range of advantages that traditional filtration media cannot match:

- High temperature resistance: suitable for continuous operation well above 500 °C.

- Pressure and abrasion resistance: maintains integrity under heavy mechanical loads.

- Reusable and cost-efficient: easy to clean and requalify for extended lifecycle use.

Chemical compatibility: resistant to aggressive fluids, acids, solvents, and corrosive media. - Uniform pore size distribution: ensures stable, repeatable filtration performance.

These characteristics make porous sintered metal the preferred choice for critical applications where reliability, longevity, and process consistency are essential.

Applications of porous sintered metal

Porous sintered metal is widely used in industries where conventional filtration media are insufficient. Typical applications include:

- Chemical and petrochemical processing

- High-pressure gas filtration

- Venting of steam and vacuum systems

- Liquid filtration at elevated temperatures

- Process streams containing aggressive or corrosive media

Due to its inherent mechanical strength, it can also be used as a structural support layer or carrier material within multi-layer filter elements.

Materials for every application

VBF Filters supplies porous sintered filter elements in several materials, each offering specific performance benefits:

- Stainless steel 316L – corrosion-resistant, durable, and fully cleanable; the industry standard.

- Bronze – suitable for lighter-duty or non-corrosive applications.

- Hastelloy – ideal for highly corrosive chemical environments and elevated temperatures.

- Inconel – excellent mechanical strength combined with superior high-temperature resistance.

- Titanium – lightweight, strong, and extremely corrosion-resistant.

Our filtration specialists are happy to advise you on the optimal material selection based on your process conditions and budget requirements.

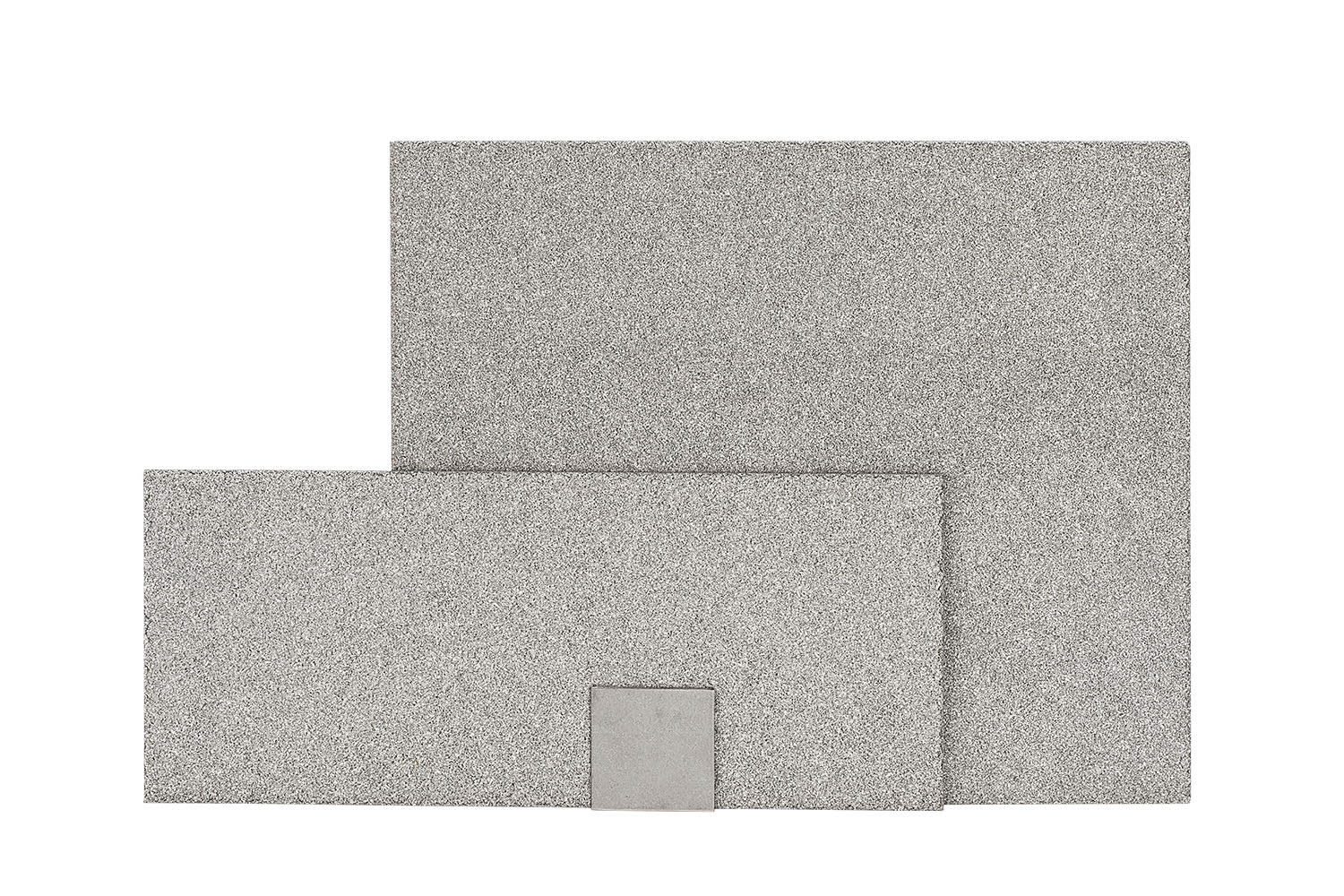

Custom-engineered solutions by VBF Filters

No two processes are the same. That’s why VBF Filters provides fully customized configurations in terms of dimensions, pore sizes, and material grades.

Whether you require standard filter elements or completely application-specific designs, we support you from initial engineering through ongoing maintenance.

With decades of experience in filtration under extreme process conditions, we know exactly which solution aligns with your application requirements.

Explore our product range

Learn more? Do you have questions or would you like more information? Fill in your details below, and our team will contact you shortly. We are happy to assist you further!

Contact us